When we buy it, the silk feels more like horse hair than silk as it is still coated with serecin, a protein gum that the silkworm secretes in order to hold the cocoon together. You can see the difference between the silk before gumming and after.

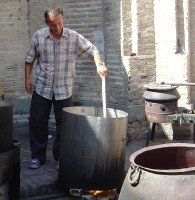

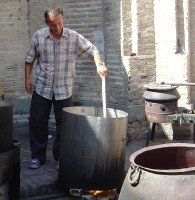

The degumming and then washing of the silk makes it whiter, softer, shinier and, well, silkier. To de-gum the silk we burn the kirk bughum (40 joints) plant, found in the desert, which results in an alkaline ash called ishkor. This is mixed into a hot bath and the silk is dunked up and down in it to strip away the seracin. The silk is then placed in a steaming hot cauldron of grated bazaar soap and washed.

There's still one more stage to go before the silk can be dyed, and that's mordanting. The word 'mordant' comes from the Latin 'to bite' and the process enables the dyes to really penetrate and fix. We use the mineral salt alum as our mordant agent heating the silk skeins in a hot alum bath and then leaving it overnight.

The dyes are cooked up in different vats (to avoid colour mixing) and heated to various temperatures (a closely guarded secret). The skeins of silk are then placed in the vat and massaged to ensure full penetration of the dyes. They are then left to cool overnight.

Once dyed, the skeins of silk are hung up to dry. They are then washed and dried again and afterwards beaten hard against the wall to soften the silk and to remove the excess, dandruff-like dye particles. The skeins are now ready for weaving.